Stainless steel oxygen ball valve

National Advisory Hotline

+86-18752587151Product description

As the opening and closing device on the oxygen pipeline in the metallurgical industry, the oxygen valve has many particularly strict requirements compared with other general valves. Because oxygen is a flammable and explosive dangerous product, it is necessary to prevent leakage, static electricity, and sparks to avoid accidents. In terms of structure, the design is: the valve stem only lifts and does not rotate when the valve disc is opened and closed, which effectively reduces the wear of the seal pair, the wear of the packing and the wear of the upper seal; the side flange is equipped with a grounding screw to avoid static sparks; The exposed part is sealed with plexiglass to prevent dust and oil.

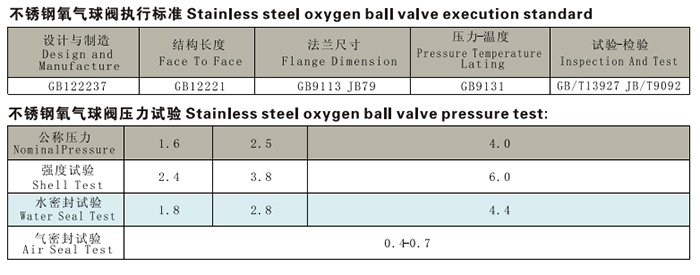

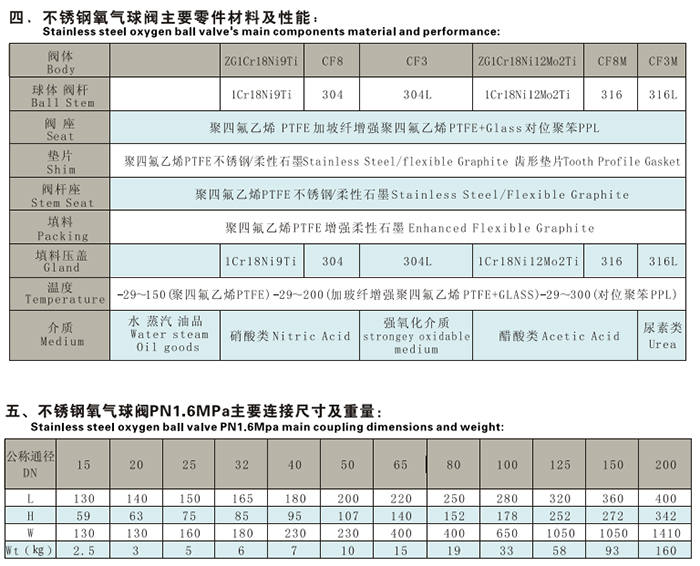

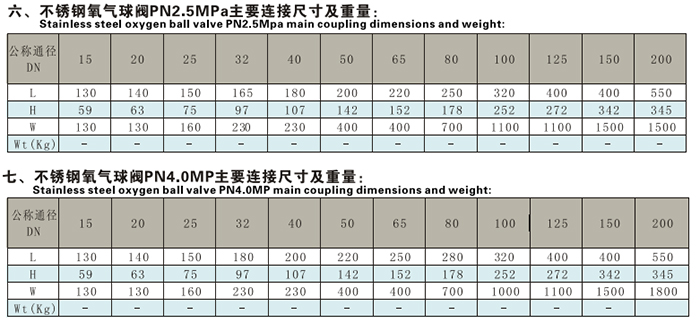

Technical parameters: The valve body material is 1Cr18Ni9Ti, the nominal pressure is PN (MPa) 1.6-4.0, the nominal diameter is DN (mm) 15-400, and the performance description has the advantages of good sealing performance, light and flexible operation, reliability, and long service life.

Recommended news

-

What are the common faults of valve special motors

2021-07-22 -

Principles of valve selection in the petroleum and ch…

2021-07-22 -

Application and principle of speed control valve

2021-07-22 -

Types and working principles of gate valves

2021-07-22 -

Do you know everything about the installation of chec…

2021-07-22 -

Why is the use of gate valves forbidden in oxygen pip…

2021-07-22 -

Introduce the working principle of high pressure angl…

2021-07-22 -

Flat gate valve use structure description characteris…

2021-07-22