Stainless steel oxygen valve

National Advisory Hotline

+86-18752587151Product description

1. This valve is mainly composed of valve body, valve cover, valve clack, and other parts

2. Spherical valve body, uniform force.

3. This valve is manually operated. Rotate the hand wheel clockwise to close the valve, and rotate the hand wheel counterclockwise to open the valve.

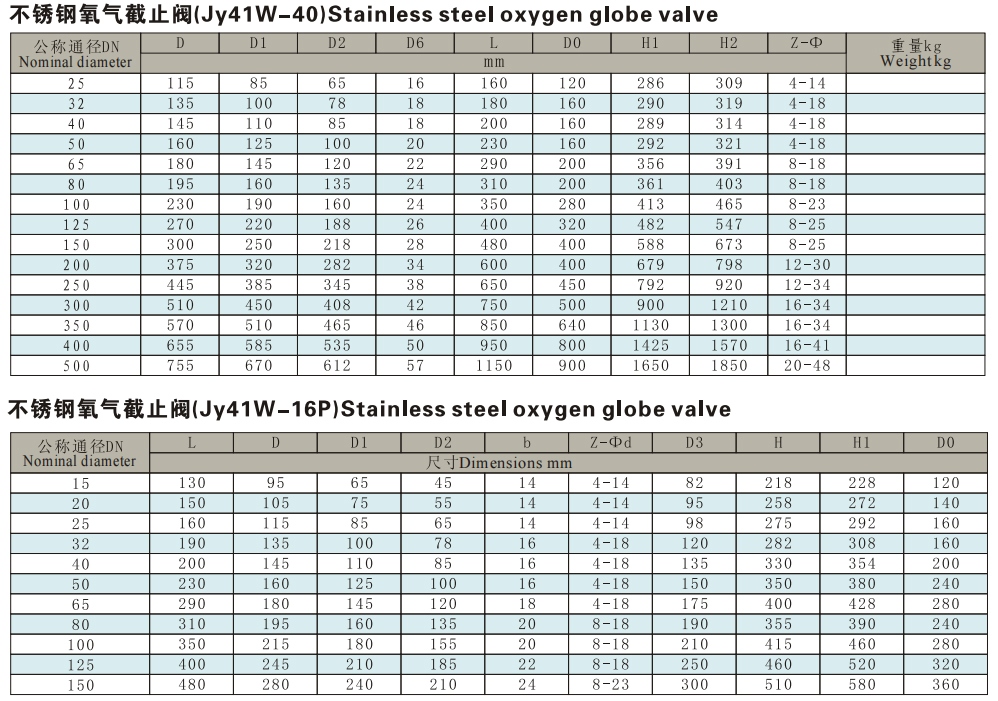

4. There are no ball bearings below DN50, and large-diameter valves such as DN150, DN200, DN250, DN300, etc. are equipped with additional discs. The flow direction of the medium flows from the upper part of the valve flap to the lower part.

Main features

1. This product is a specially designed stainless steel or copper alloy shut-off valve, which is mainly used for the pipeline after the oxygen compressor is pressurized.

2. Flexible opening and closing. This valve adopts two structures according to the size of the diameter, the small diameter is the ordinary structure, and the large diameter is additional auxiliary valve clack. To balance the pressure difference between the front and back of the valve to reduce the opening and closing torque.

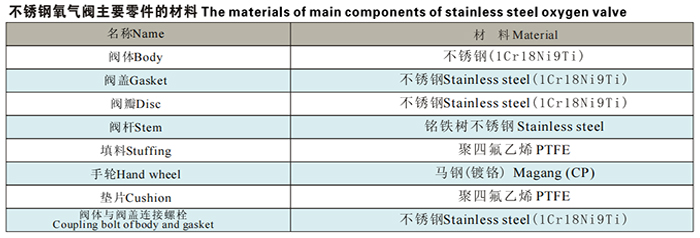

3. Safe and reliable. The valve is manufactured with strict oil prohibition measures, the packing material is PTFE, and the valve stem is designed as a lifting rod, that is, the valve stem does not rotate when it is raised and lowered, and the valve flap rises and falls with it, thus reducing the wear on the packing. Seal wear is also reduced to a low level. All valves are strictly degreased before installation to ensure safe and reliable use.

4. The exposed part of the valve stem has protective measures to prevent dust and oil. The lubrication of the bracket bearing adopts fluorinated grease.

Precautions in installation

1. This product has passed the following inspections before leaving the factory:

●The air tightness and hydraulic strength test of the valve;

●Opening and closing test after valve assembly;

●The valve must be installed strictly and comply with the requirements of "Code for Construction Acceptance of Degreasing Engineering" before degreasing.

2. The installer must comply with the relevant requirements of the "Oxygen Safety Specification" and strictly prohibit contact with oil.

3. It is strictly forbidden to use afterburner levers for all diameter handwheels. For valves with auxiliary discs, the main disc should be opened after the auxiliary disc is opened for a period of time before and after the pressure of the valve is close to equilibrium.

4. There are conductive bolt holes at the flange end of the valve, which requires good grounding to prevent static electricity.

5. It is recommended that the valve stem be vertically upward for the installation position of the valve.

6. The flange of this valve is a concave-convex MFM flange. The user must prepare the anti-flange on the connecting pipe according to the GB/T 9113 standard (see the appendix for assembly dimensions), but when the user requests it, the anti-flange It can also be supplied as a valve add-on.

Recommended news

-

What are the common faults of valve special motors

2021-07-22 -

Principles of valve selection in the petroleum and ch…

2021-07-22 -

Application and principle of speed control valve

2021-07-22 -

Types and working principles of gate valves

2021-07-22 -

Do you know everything about the installation of chec…

2021-07-22 -

Why is the use of gate valves forbidden in oxygen pip…

2021-07-22 -

Introduce the working principle of high pressure angl…

2021-07-22 -

Flat gate valve use structure description characteris…

2021-07-22